Discover the Benefits of Regular Strapping Machine Service for Improved Efficiency and Longevity

Routine strapping machine service plays a crucial function in optimizing manufacturing procedures. Firms that prioritize upkeep experience improved effectiveness and decreased downtime. This proactive method can help identify possible issues early, resulting in significant expense savings. Lots of organizations ignore the importance of regular service. Comprehending the full extent of benefits can reshape operational approaches and improve general efficiency. What are the essential advantages that come from this essential technique?

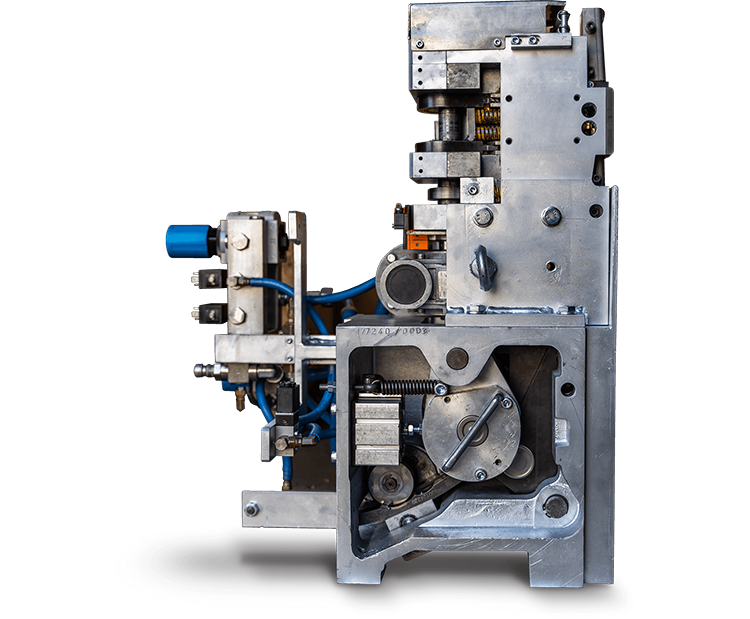

Comprehending the Significance of Strapping Machine Upkeep

While lots of services prioritize manufacturing efficiency, the importance of strapping machine upkeep commonly goes overlooked. Regular maintenance is important for assuring that strapping makers run at peak efficiency degrees. Disregarding this element can lead to unforeseen breakdowns, which interfere with workflow and increase downtime. Proper maintenance assists to recognize deterioration prior to it escalates right into significant issues, eventually prolonging the life expectancy of the equipment. Additionally, routine checks ensure that the equipments generate regular, top quality strapping, minimizing the risk of damages to products during delivery and storage. By investing time and sources into maintenance, organizations can avoid pricey fixings and foster a more dependable manufacturing environment, thus supporting general functional objectives in the future.

Enhanced Functional Performance

Improved operational efficiency is a crucial advantage of routine strapping machine service. By making certain that machines are well-kept and working successfully, services can substantially reduce downtime triggered by breakdowns or inadequacies. Routine servicing assists identify and deal with potential issues prior to they rise, making it possible for smooth procedures. This proactive method means that strapping machines operate at peak efficiency, promoting quicker manufacturing cycles and reducing the threats connected with unforeseen failures. Furthermore, a well-tuned machine can take care of boosted work without endangering top quality, allowing for higher throughput. Eventually, boosted operational effectiveness equates into a more structured workflow, encouraging business to meet demand effectively and enhance overall efficiency in their product packaging procedures. Regular maintenance consequently plays a necessary duty in attaining operational excellence.

Expense Cost Savings Via Preventative Maintenance

Regular maintenance of strapping devices not just boosts functional performance yet also brings about substantial expense financial savings with preventative upkeep. By determining and resolving minor issues before they intensify into significant issues, business can stay clear of costly repair work and downtime - strapping machine service. Normal examinations aid assure that parts work at peak performance, lowering the danger of unanticipated failures that can interrupt manufacturing timetables. Additionally, constant maintenance can cause more efficient energy usage, decreasing utility costs with time. Effective preventative maintenance practices also enable services to intend their spending plans better, as expenses end up being a lot more foreseeable. Inevitably, buying normal service translates to lasting monetary advantages, making it a wise strategy for any type of organization reliant on strapping machinery

Extending the Lifespan of Your Tools

Routine maintenance checks play a crucial duty in lengthening the life expectancy of strapping makers. Prompt repairs and making use of top quality replacement parts further guarantee that equipment continues to be in ideal problem. By focusing on these methods, organizations can significantly improve the longevity and reliability of their strapping machines.

Normal Upkeep Checks

Strapping devices are designed for toughness, ignoring regular upkeep checks can significantly reduce their lifespan. Regular assessments assist recognize deterioration prior to they escalate into substantial issues. Routine maintenance assurances that all parts function at their finest, minimizing the risk of unforeseen failures and enhancing overall efficiency. During these checks, parts such as sensors, motors, and belts can be cleansed and lubed, protecting against friction and getting too hot. Additionally, calibration of the machine settings can Homepage be executed to maintain exact operation, additional expanding its longevity. By establishing a regular maintenance routine, businesses can ensure their strapping equipments operate effectively, saving time and decreasing costs connected with tools failure. Ultimately, regular maintenance checks are important for making best use of the lifespan and reliability of strapping devices.

Prompt Services Significance

Prompt repairs are vital for keeping the operational efficiency and longevity of strapping makers. Addressing them quickly prevents small troubles from escalating right into considerable malfunctions that could lead to pricey downtime when problems develop. Regular servicing permits drivers to determine wear and tear early, guaranteeing devices function effectively. Timely repair work help maintain the top quality of strapping processes, which is vital for product integrity and customer contentment. Disregarding repair services can lead to increased power usage and reduced efficiency, adversely affecting general operational prices. By focusing on prompt fixings, services can prolong the life expectancy of their strapping equipment, eventually protecting their financial investment and improving overall performance in manufacturing lines. Consistent interest to repairs is vital to sustained efficiency.

Quality Substitute Components

Purchasing top quality replacement components is necessary for extending the life-span of strapping equipments. High-quality elements assure peak performance and integrity, reducing the probability of breakdowns and expensive repair services. When substandard parts are utilized, they can trigger additional stress on the equipment, leading to more frequent failures and a shorter operational life. Furthermore, quality replacement parts commonly come with better guarantees, giving added peace of mind for operators. Making use of initial equipment producer (OEM) parts can further improve compatibility and efficiency, making certain that the strapping machine runs as planned. Normal site link maintenance, integrated with using high quality components, produces a collaborating result that makes the most of performance, reduces downtime, and eventually adds to the long-lasting success of business.

Reducing Downtime and Disruptions

As production routines come to be progressively requiring, decreasing downtime and interruptions in strapping machine operations is essential for preserving efficiency. Normal servicing of strapping machines can significantly decrease the likelihood of unanticipated break downs. Scheduled upkeep enables for very early detection of possible problems, making certain that all elements work at their ideal. This positive strategy not only protects against expensive stops in manufacturing yet additionally prolongs the life-span of the devices. In addition, well-kept devices operate smoothly, lowering the chances of functional hiccups that might interfere with process. By purchasing routine service, services can develop a more reliable production setting, boosting total efficiency and conference limited delivery deadlines. Eventually, decreasing downtime through normal maintenance techniques is vital for sustaining efficient strapping procedures.

Making Sure Constant Quality and Performance

While preserving a high degree of performance, ensuring consistent high quality and performance in strapping makers is crucial for any assembly line. Regular servicing plays an essential function in this aspect, as it assists recognize and fix prospective problems before they escalate. A well-maintained strapping machine delivers consistent tension and secure seals, which are critical for product packaging honesty. On top of that, regular efficiency reduces the risk of product damages throughout transportation, inevitably enhancing client contentment. By buying regular maintenance, firms can enhance their strapping operations, ensuring that machinery runs at peak ability. This aggressive technique not only prolongs the lifespan of the equipment yet likewise guarantees that production criteria are met constantly, promoting reliability in the overall manufacturing process.

Frequently Asked Inquiries

Exactly How Often Should Strapping Machines Be Serviced?

Strapping machines need to ideally be serviced every six months to ensure peak performance. Usage frequency and functional problems may demand much more regular inspections, guaranteeing durability and performance in their procedure.

What Are Common Indicators That My Strapping Machine Needs Servicing?

Common indications that a strapping machine requires servicing consist of constant jams, irregular tension, unusual noises, noticeable endure components, and erratic operation. strapping machine service. Attending to these concerns without delay can prevent further damages and warranty top performance

Can I Execute Maintenance on My Strapping Machine Myself?

Yes, a person can execute standard upkeep on a strapping machine, such as cleansing and lubrication. For considerable fixings or maintenance, specialist help is suggested to ensure peak efficiency and longevity.

What Kinds Of Strapping Machines Require Service?

Various kinds of strapping equipments, including semi-automatic, automated, and portable versions, need routine service. Each type may have special maintenance demands, but all benefit from regular checks to ensure peak performance and durability.

Exist Certain Company for Various Strapping Machine Brands?

Yes, particular company usually focus on various strapping machine brand names. These suppliers have the necessary expertise and parts to ensure peak upkeep and repair work customized to the distinct needs of each brand's equipment.

Improved operational effectiveness is an important advantage of routine strapping machine service. Normal servicing of strapping machines not only enhances operational effectiveness yet likewise leads to considerable price savings with preventative upkeep. Regular maintenance checks play an essential function in lengthening the life expectancy of strapping machines. By establishing a regular maintenance timetable, businesses can ensure have a peek at this site their strapping equipments operate efficiently, saving time and minimizing prices associated with equipment failure. Yes, a person can execute basic maintenance on a strapping machine, such as cleansing and lubrication.